Phosphating

We are a first-class company in Chennai in the field of Phosphating Plant. For any questions contact us for a free quote!

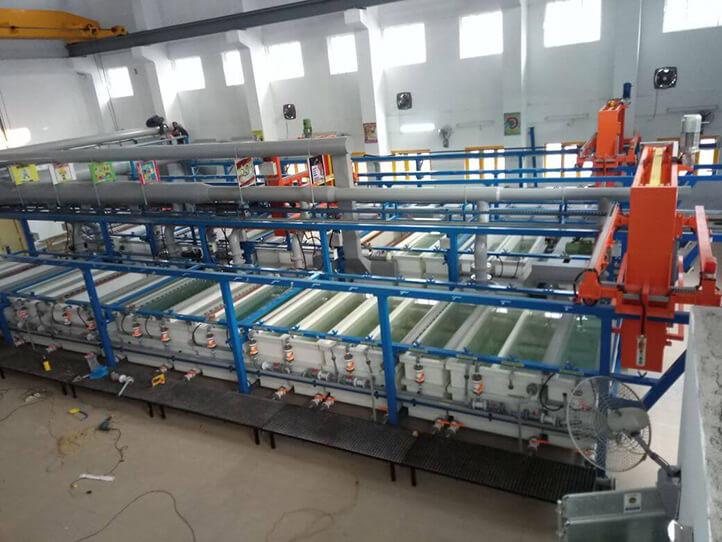

Our plant that is offered is fabricated through the use of the highest value raw material and also highly improved technology by our most recent professionals. As a way to be sure of caliber, this plant has been meticulously analyzed on various parameters. In song with industry standards, we provide the whole range following the ever-evolving requirements of our clientele.

Phosphating can be called phosphate coating can be a special conversion coating applied into the ferrous metal ostensibly utilized with a different corrosion protection system in lots of businesses either to realize exceptional corrosion resistance combined to fortify the friction faculties of slipping components. This processing can be referred to as the pre-treatment from several companies before painting or coating. The synthesis of this phosphating process might be reached by utilizing zinc, iron, or manganese phosphate.

A deeper understanding subjective into the phosphating could be caused by our deep expertise in the allied industry using a rigorous to provide an excellent solution connected with Sri Vinayaga Fibre. Our group of professionals includes a commendable specialization in upgrading and producing the high-quality of this phosphating process plant that allows one to reach the right surface finish combined side required a depth of this coat.

WHY CHOOSE US

To successfully satisfy the luxury essentials of the customers, we’ve got developed a state-of-the-art infrastructure in Sri Vinayaga Fibre. It’s supported by a team of professionals, who possess years of working experience within their several domain names. We follow the top quality testing procedure to make sure these services and products, invented by us are perfect and consistent with the global quality standards according to ISO. Our commitment to quality and making an effort to supply maximum client satisfaction has allowed us to advance widely in a variety of places in the nation.

OUR MISSION

We keep our customers updated with the latest trends and new developments in our business. We also believe that all the technical inputs/awareness of what we provide to the customer, regarding the chemicals and the process should percolate up to the operator level. The well-trained and responsible operator will only assure the product quality of the customer as well as the best performance of our chemicals.